Blog

- Home

- /

- Blog

What is Textile Dyestuff and How is it Used?

Textile dyestuff plays a crucial role in transforming raw fabrics into vibrant pieces of art. It involves various chemical compounds used to impart color to textiles. The process is intricate and requires expertise to achieve the desired hue and shade.

Different types of textile dyestuffs exist, each with unique properties. Some are natural, derived from plants and minerals. Others are synthetic, created through chemical processes. The choice of dyestuff impacts the fabric's appearance, texture, and durability.

However, not all textile dyestuff is eco-friendly. Some chemicals can harm the environment. This raises important questions about sustainability in the textile industry. As consumers become more conscious, the demand for eco-friendly dyes is growing. This shift challenges producers to innovate and adapt their practices.

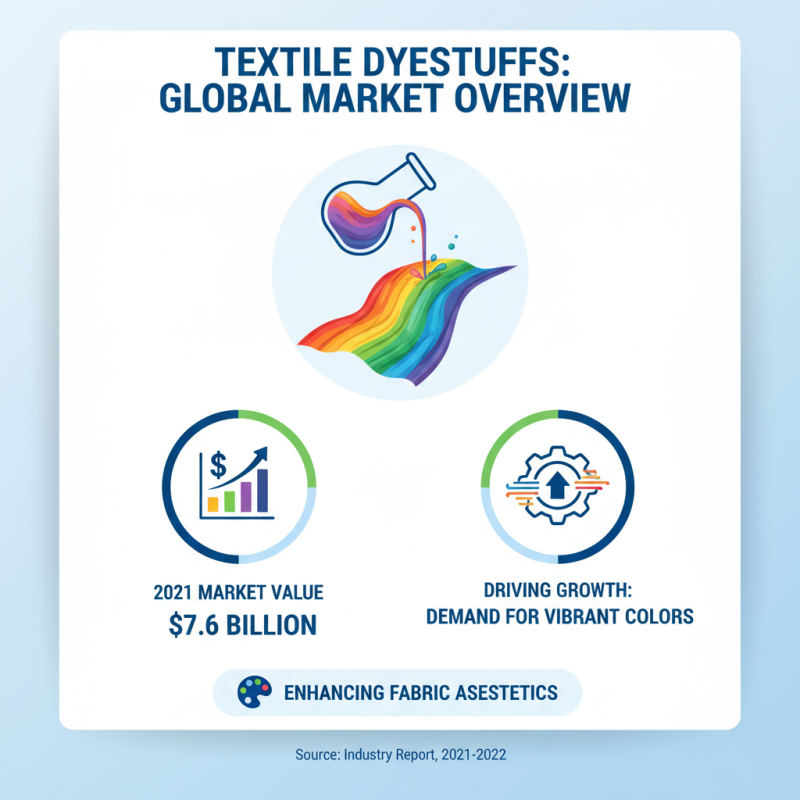

What is Textile Dyestuff? A Definition and Overview

Textile dyestuff refers to the chemicals used in dyeing fabrics. This process enhances the aesthetic appeal of textiles. In 2021, the global textile dyes market was valued at approximately $7.6 billion. The increasing demand for vibrant colors drives growth in this sector.

The production of textile dyestuff involves complex chemical processes. Natural and synthetic dyes are widely used. Natural dyes come from plants and animals, while synthetic dyes are made from petrochemicals. Each type has its advantages and drawbacks. Natural dyes tend to be less harmful but may have limited color fastness. Synthetic dyes offer a broader color spectrum but can pose environmental risks.

Tips: Always test dyestuff on fabric scraps before full application. Additionally, consider the environmental impact of your choice. Using eco-friendly alternatives can reduce pollution and waste. Remember, while color matters, sustainability should also be a priority. Embracing biodegradable dyes can lead to a more responsible approach in fashion and textile industries.

The History of Textile Dyestuffs: From Natural to Synthetic

The journey of textile dyestuffs is fascinating. Originally, natural dyes were used for coloring fabrics. These dyes came from plants, insects, and minerals. For example, indigo from the indigo plant gave textiles a rich blue hue. Similarly, cochineal, derived from insects, produced vibrant reds. These colors were beloved, but making them was often time-consuming and labor-intensive.

As the industrial revolution progressed, the demand for textiles skyrocketed. This led to the discovery of synthetic dyes. These man-made alternatives allowed for vibrant colors and easier production. They were often more stable and cheaper than natural dyes. However, this shift was not without its problems. The environmental impact of creating synthetic dyes raised concerns. The use of harmful chemicals affected both ecosystems and human health.

Today, we face a dilemma. Innovations in dye technology continue, but sustainability is a pressing issue. Many contemporary brands are seeking eco-friendly solutions. Yet, challenges remain. Balancing colorfastness, safety, and environmental impact is complex. The history of textile dyestuffs highlights our need to reflect on our choices. It encourages a conversation about the future of color in textile design.

Textile Dyestuffs Usage Over Time

This chart illustrates the distribution of textile dyestuff usage, highlighting the prevalence of synthetic dyes over natural dyes throughout history.

Types of Textile Dyestuffs and Their Chemical Properties

Textile dyestuffs play a crucial role in the fabric industry. They provide the vibrant hues we see in clothing and textiles. Dyestuffs come in various types, including natural and synthetic options. Natural dyes derive from plants, insects, and minerals. They often produce softer colors but have varying lightfastness. Synthetic dyes are more consistent and can create bright, long-lasting shades.

The chemical properties of textile dyestuffs vary widely. For instance, direct dyes bond well with cellulose-based fibers like cotton. Reactive dyes, on the other hand, form strong covalent bonds with fibers, making them quite popular. Acid dyes are usually used for protein fibers such as wool and silk. Each type brings unique benefits and challenges, often leading to reflections on sustainability and environmental impact.

Some dyes require strict pH control during application. Improper usage can result in poor color uptake. This raises questions about waste management and resource use in dyeing practices. Ultimately, choosing the right dyestuff involves balancing color vibrancy with ecological considerations. It's a complex process that demands continuous improvement and innovation.

What is Textile Dyestuff and How is it Used? - Types of Textile Dyestuffs and Their Chemical Properties

| Type of Dyestuff | Chemical Structure | Color Range | Common Uses |

|---|---|---|---|

| Reactive Dyes | Reactive groups bonded to chromophore | Wide range including bright colors | Cotton, rayon, and other cellulose fibers |

| Acid Dyes | Anionic dyes with sulfonic or carboxylic groups | Vibrant colors, especially reds and blues | Wool, silk, and synthetic fibers |

| Vat Dyes | Reduced form that can be re-oxidized | Deep shades including indigo | Cellulosic fibers, especially cotton |

| Sulfur Dyes | Thiosulfonate compounds | Dark and muted shades | Cotton and viscose fibers |

| Disperse Dyes | Non-ionizable, small molecules | Brilliant colors | Synthetic fibers like polyester |

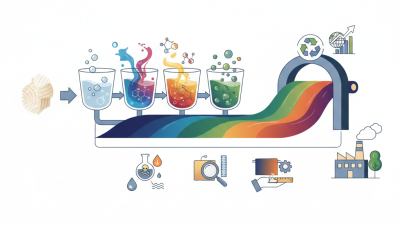

The Dyeing Process: Techniques and Methods in Textile Production

The dyeing process in textile production involves various techniques and methods. Fabric can be dyed in several ways, such as direct dyeing, resist dyeing, and tie-dye. Each method offers unique results. For example, direct dyeing allows vibrant colors but may fade over time. It's essential to choose the right method based on fabric type and desired aesthetic.

Another method is screen printing, which applies color in specific patterns. This technique is precise but can be limited by the complexity of designs.

Furthermore, the dyeing process often reflects environmental challenges. Many synthetic dyes can harm ecosystems. Natural dyes present an alternative but require more effort to achieve consistency. Rethinking dye choices is crucial for sustainability. The textile industry must balance creativity with responsibility. Each method poses unique problems that require careful consideration.

Environmental Impact and Sustainability of Textile Dyestuffs

Textile dyestuffs are essential for coloring fabrics. However, their environmental impact raises concerns. Many dyes contain harmful chemicals. These substances can pollute water and soil. This leads to health issues for workers and nearby communities.

Sustainability in dye production is gaining importance. Natural dyes can be a viable alternative. They are derived from plants and minerals, making them less toxic. However, sourcing these materials can be challenging. The availability and process can vary widely.

Tips: Consider using natural dyestuffs when possible. They may require experimentation but can reduce your environmental footprint. Always check local sources for safety practices. There’s also a growing market for eco-friendly dyes; explore these options for better sustainability. Awareness of dye impacts can lead to better choices for consumers. Making informed decisions is key.

Related Posts

-

What is Textile Colouring and How Does it Impact Fabric Quality and Design

-

Comprehensive Guide to Textile Dyeing Chemicals List for Professionals

-

How to Choose the Best Textile Processing Chemicals for Your Needs

-

2025 Guide: How to Choose the Best Textile Fabrics for Your Projects

-

2025 Top 10 Textile Auxiliaries Innovations Driving Sustainability and Efficiency

-

How to Capture Stunning Textile Photos That Showcase Your Fabric's Beauty