Blog

- Home

- /

- Blog

Top 10 Textile Chemicals and Auxiliaries You Need to Know in 2023

In the ever-evolving landscape of the textile industry, understanding the vital role of textile chemicals and auxiliaries is crucial for manufacturers aiming to enhance their production processes and improve the quality of their products. Industry expert Dr. Emily Thompson, a leading chemist in textile applications, emphasizes the significance of these substances by stating, “The right selection of textile chemicals and auxiliaries can make a substantial difference in durability, efficiency, and environmental sustainability.”

As we explore the top 10 textile chemicals and auxiliaries you need to know in 2023, it becomes apparent that innovation and sustainability are at the forefront of this sector. The importance of these chemicals extends beyond mere functionality; they play a pivotal role in the sustainability practices that are increasingly demanded by consumers and regulatory bodies alike. Understanding which chemicals can enhance performance while minimizing environmental impact is essential for any textile producer in the modern market.

Moreover, embracing these advanced solutions not only leads to higher quality fabrics but also contributes to a more sustainable future in textiles. As we delve into this comprehensive list, we will uncover the transformative potential these chemicals hold, paving the way for advancements in both product development and environmental stewardship within the textile industry.

Overview of Textile Chemicals and Auxiliaries

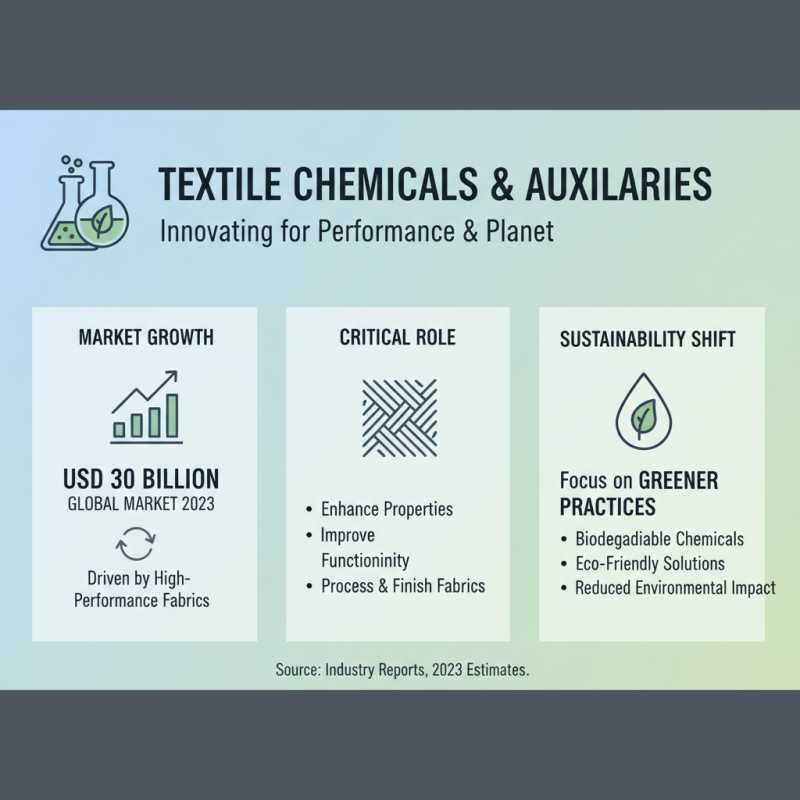

Textile chemicals and auxiliaries play a critical role in the fabric production process, greatly enhancing the properties and functionalities of textiles. In 2023, the global textile chemicals market is expected to reach approximately USD 30 billion, according to industry reports. This growth can be attributed to the increasing demand for high-performance fabrics and sustainable materials, which require specialized chemicals for processing and finishing. This heightened focus on sustainability is driving innovations in biodegradable and eco-friendly chemicals, responding to the textile industry's shift toward greener practices.

Auxiliaries, which encompass a wide range of chemicals used during various stages of textile production, are essential for processes such as dyeing, finishing, and printing. For instance, surfactants, enzymes, and dyes serve specific purposes, from improving fabric wetting to enhancing color stability. In particular, the enzyme market within textile applications is projected to grow significantly, with a compound annual growth rate (CAGR) of around 9% over the next five years. This shift towards enzymatic solutions reflects a growing preference for efficient and environmentally friendly processes that reduce water and energy consumption in production and lead to less toxic waste. Overall, the landscape of textile chemicals and auxiliaries is changing, with sustainability and innovation at the forefront of the sector.

Key Properties and Functions of Textile Chemicals

In 2023, understanding the key properties and functions of textile chemicals and auxiliaries is essential for anyone involved in the textile industry. Textile chemicals encompass a wide range of substances used in various stages of textile production, including preparation, dyeing, finishing, and printing. According to a recent report by ResearchAndMarkets, the global textile chemicals market is projected to reach approximately USD 25 billion by 2025, driven by the increasing demand for advanced textile functionalities and eco-friendly processes.

Among the key properties of textile chemicals are their ability to enhance durability, colorfastness, and comfort of fabrics. For instance, softeners improve the hand feel and drape of textiles, while durable water repellents (DWR) offer functional benefits for outdoor garments. Moreover, specialty chemicals such as anti-microbial agents play a pivotal role in hygiene and odor control, responding to consumer demand for health-conscious textiles. Reports indicate that the demand for such functional treatments has surged, with anti-microbial textiles expected to grow at a CAGR of 6.9% through 2027.

Auxiliaries also contribute significantly to the efficiency of textile processes. For example, enzymes used in bio-polishing not only enhance fabric appearance but also reduce the environmental impact by lowering water usage and energy consumption during processing. The integration of green chemistry principles has further escalated the adoption of sustainable textile chemicals, reflecting a broader trend towards environmentally responsible production methods in the textile sector. As the industry evolves, staying informed about these chemical functionalities will be crucial for innovation and competitiveness.

Top 10 Textile Chemicals and Auxiliaries You Need to Know in 2023 - Key Properties and Functions of Textile Chemicals

| Chemical Name | Key Properties | Functions | Applications |

|---|---|---|---|

| Dyes | Colorfastness, stability | Coloring fabrics | Apparel, home textiles |

| Surfactants | Wettability, emulsification | Detergency, softening | Fabric washing |

| Finishing Agents | Softness, water-repellency | Improving tactile properties | Home textiles |

| Binders | Adhesiveness, durability | Binding fiber together | Nonwovens |

| Bleaching Agents | Whiteness, brightness | Whitening fabrics | Cotton processing |

| Anti-foaming Agents | Foam control | Eliminating foam during processing | Dyeing, washing |

| Biocides | Antimicrobial properties | Preventing mold and bacteria | Textile preservation |

| Color Fixatives | Improved dye absorption | Fixing dyes on the fabric | All types of dyed textiles |

| Flame Retardants | Flame resistance | Reducing flammability | Safety textiles |

| Hydrophilicity Agents | Increased moisture absorption | Enhancing comfort | Sportswear, activewear |

Top Textile Dyes and Their Applications in 2023

In 2023, the textile industry continues to evolve, with innovative dyes playing a crucial role in enhancing fabric aesthetics and performance. One prominent category is reactive dyes, renowned for their ability to form strong covalent bonds with fibers, ensuring vibrant colors that withstand washing and light exposure. These dyes are particularly favored in the production of cotton and cellulosic textiles, offering a broad spectrum of shades, which appeals to designers looking for sustainable and durable solutions.

Another significant development comes from the realm of pigment dyes. Unlike traditional dyes, pigments are insusceptible to washing, making them ideal for applications where colorfastness is essential. They provide an array of colors and can be used on various substrates, including synthetic fibers. The versatility of pigment dyes allows manufacturers to create unique prints while also adhering to eco-friendly practices, as many of these pigments are water-based and less hazardous to the environment.

Natural dyes, sourced from plant, animal, or mineral origins, are gaining traction as consumers increasingly prioritize sustainability. These dyes are not only biodegradable but also offer unique color palettes that cannot be replicated by synthetic alternatives. From indigo extracted from leaves to cochineal derived from insects, natural dyes provide an organic solution that resonates with eco-conscious brands aiming to reduce their environmental impact while delivering rich, authentic colors to consumers.

Innovative Auxiliaries Enhancing Textile Production

The textile industry is continuously evolving, and innovative auxiliaries are playing a crucial role in enhancing textile production. These advanced chemicals are designed to improve various aspects of fabric processing, from dyeing and printing to finishing and performance enhancement. One notable trend in 2023 is the integration of eco-friendly auxiliaries that not only meet sustainability demands but also boost production efficiency. These environmentally conscious solutions are paving the way for reducing waste and improving the overall carbon footprint of textile manufacturing.

Additionally, smart auxiliaries are making waves in the textile sector by offering functionalities like moisture management, stain resistance, and UV protection. These innovations are not merely add-ons but essential components that can elevate the value of textiles in a competitive market. The use of nanotechnology and biopolymers, for example, is leading to the development of fabrics that are both durable and adaptable, catering to consumer demands for high-performance textiles without sacrificing comfort or safety. Such advancements are key for manufacturers aiming to stay ahead in an industry that increasingly prioritizes quality, functionality, and sustainability.

Environmental Impact and Sustainability in Textile Chemistry

The textile industry has long been scrutinized for its environmental footprint, and as we move through 2023, a growing emphasis on sustainability is reshaping the landscape of textile chemistry. Manufacturers are increasingly urged to adopt eco-friendly chemicals and auxiliaries that minimize pollution and reduce waste. Sustainable textile chemistry focuses on biodegradable, non-toxic materials that can improve the lifecycle of textile products while safeguarding ecosystems.

Incorporating sustainable practices is essential not only for compliance but also for the overall health of our planet. By choosing biodegradable dyes and waterless dyeing techniques, the industry can significantly reduce harmful runoff and energy consumption. Furthermore, the use of enzymes in processing can lower the need for harsh chemicals, thus promoting a more sustainable production cycle.

Tips for implementing sustainability in textile chemistry include:

- Opt for locally sourced materials to reduce transportation emissions.

- Invest in technology that improves water and energy efficiency in dyeing processes.

- Educate staff and stakeholders on the importance of eco-friendly practices to foster a culture of sustainability.

As consumers become more eco-conscious, businesses that prioritize environmentally friendly chemicals will not only comply with regulations but also gain a competitive edge in the market.

Related Posts

-

2025 Top 10 Textile Auxiliaries Innovations Driving Sustainability and Efficiency

-

2025 Top 10 Types of Dyes Revolutionizing the Textile Industry

-

Exploring Innovations in the US Textile Industry and Their Impact on Sustainability

-

What is Textile Colouring and How Does it Impact Fabric Quality and Design

-

Comprehensive Guide to Textile Dyeing Chemicals List for Professionals

-

Why Choosing the Right Distributor Textile Can Boost Your Business Growth by 30%